Description

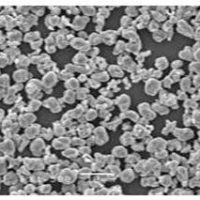

- For BASF Ultrafuse 316L.

- The system is also available as a single debinding system or single furnace system with extended working space. (250 mm x 250 mm x 250 mm)

Options (view related products)

- Hydrogen kit 100% operation

- High vacuum kit 10e-4 mbar

- PC Operation / Data storage

- Chiller for cooling water

General Conditions

- Payment schedule

- 40% in advance

- 50% after factory acceptance test

- 10% after site acceptance test

- Warranty

- The lesser of 12 months after acceptance test or 14 months after date of delivery

- Excludes wear parts

- Delivery Time

- 6 months after receipt of order and first payment